Not your typical chemical company

Innovative solutions designed to meet the toughest industrial challenges

Our Technology

Our Bioforge platform brings versatility and precision to the manufacturing process, cutting inefficiencies, reducing costs, and delivering unmatched performance tailored to your unique needs.

The Bioforge Advantage

- 1Sustainable Feedstocks

- 2Efficient Processes

- 3Local Supply Chains

Metal Catalysis

After the enzyme oxidation reactor, our engineered metal catalysts convert the material into a near final product, with higher selectivity, higher conversion, and lower temperatures than traditional processes.

After the enzyme oxidation reactor, our engineered metal catalysts convert the material into a near final product, with higher selectivity, higher conversion, and lower temperatures than traditional processes.

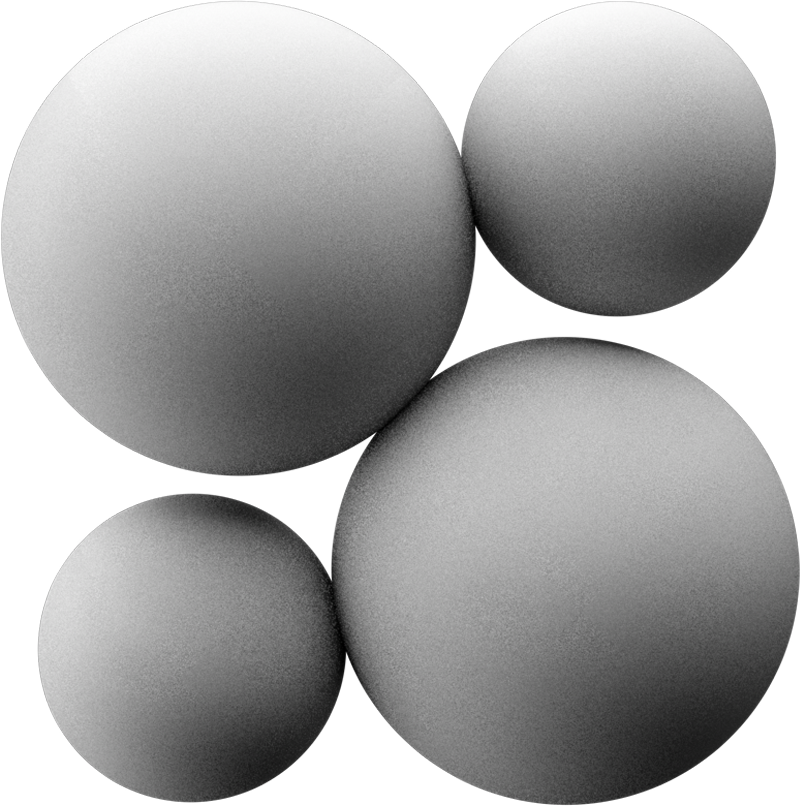

Modularity

The Bioforge can be built anywhere at speed and scale—decentralizing manufacturing and creating safer conditions for both humans and the Earth.

The Bioforge can be built anywhere at speed and scale—decentralizing manufacturing and creating safer conditions for both humans and the Earth.

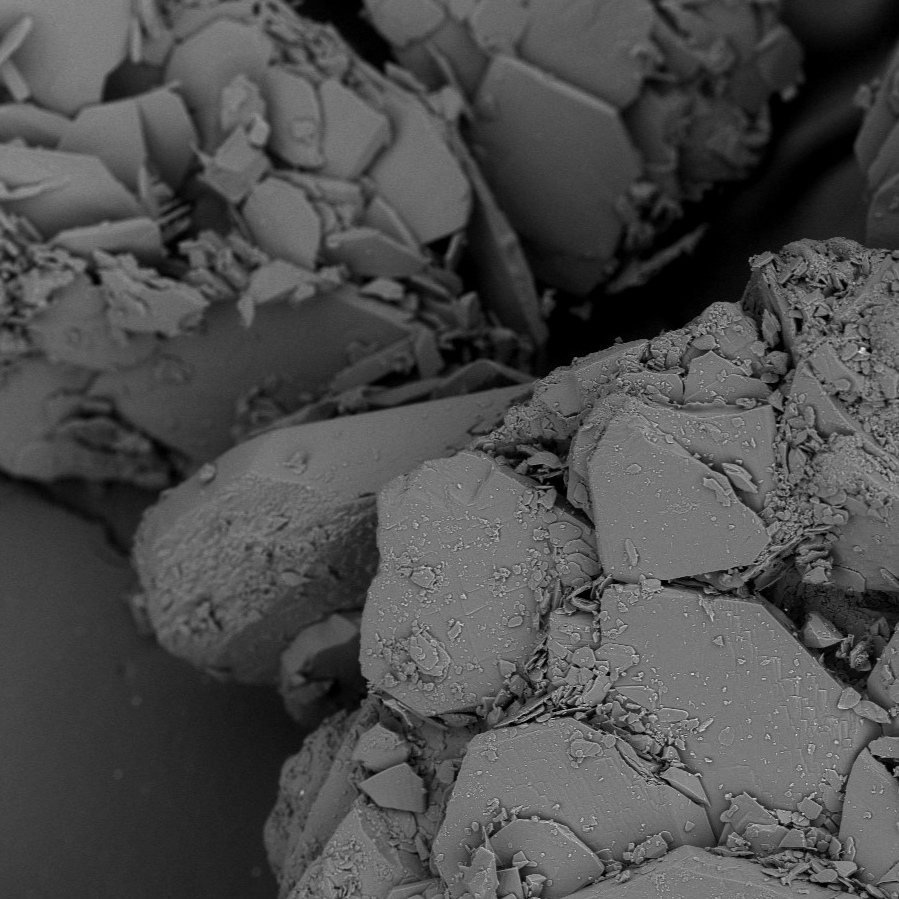

Engineered Enzymes

Sustainable feedstocks are fed into our cell-free enzyme oxidation reactor, which begins the highly efficient conversion process with low energy input.

Sustainable feedstocks are fed into our cell-free enzyme oxidation reactor, which begins the highly efficient conversion process with low energy input.

Yield

1 ton of product is made for every 1 ton of feedstock. The only downstream steps involve an evaporator to remove water and a crystallizer to create a solid final product.

1 ton of product is made for every 1 ton of feedstock. The only downstream steps involve an evaporator to remove water and a crystallizer to create a solid final product.